Denim, What Can We Do With It?

Denim is, by definition, a material designed to last. Jacob W. Davis proved it right when he made the first pair of denim jeans back in 1873, after receiving an special order from a female customer who wanted a pair of durable pants for her husband to chop wood. The success was immediate, and denim jeans have become one of the largest icons of American culture ever since.

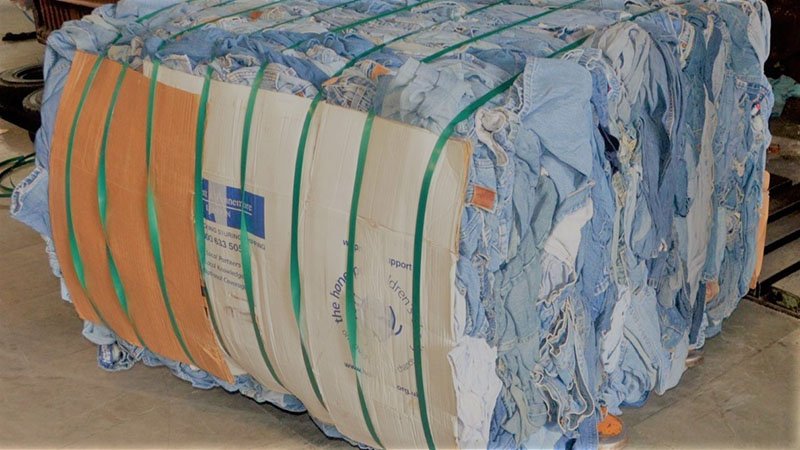

In fact, seven percent of total used clothing is denim. Every day, you can see men, women, kids, and young people wearing denim jeans, shirts, jackets, skirts, vests, etc. Garments that often end up in a bale of used clothing.

Taking a deeper look into the discarded denim products that end up in the used clothing grading facilities, we can see that only nine percent of them are made out of 100% cotton. In other words, less than one in ten pieces of denim clothing is woven using only a naturally grown material. The rest are made utilizing a blend of synthetic, artificial, and natural materials which are difficult to recycle commercially.

So, the question is, what can we do with this 7%?

More Secure, Yet Costly Imports of Used Products in Pakistan

If are running a thrift store or you are a private collector who sells your used products to Pakistan, you may have noticed more tedious paperwork in your last order(s). This is mainly because of a new resolution from the State Bank of Pakistan, which enforces Pakistani customers to use Letters of Credit or, at least, Contract Letters for the payment of their imports.

This payment process that involves couriering of original documents – invoice and B/L -, takes about two weeks and has a total fee of about $280 USD. It has delayed the purchase of mixed rags from Pakistan, and increased the cost for the importers. Luckily, importers and sellers are getting used to it, it seems, sharing the weight of the extra cost and paperwork, looking forward to benefit their long term relationships.

Wait Times Count Towards the Driving Hours

Andrew has been a driver for his 53’ truck since 2003. He used to work about 100 hours per week, moving mixed rags and other used products across the States and Canada. He would drive for 8 hours to get to the seller warehouse, then take a 2 hour nap while his truck was loaded with the bales of used clothing. After, he hit the road again for another 6 hours of driving before he stopped for a proper rest. That’s no longer the case.

Since the implementation of the ELD mandate in December, Andrew can’t drive for more than 11 hours in a consecutive on-duty window of 14 hours. Then, he is enforced to 10 consecutive hours off-duty. What is the direct effect of the ELD for thrift stores, private collectors, and graders? This measure has translated into a decrease on truck availability and an increase on shipping prices.

For that reason, now more than ever it is specially important to load trucks efficiently, maximizing the weight and minimizing the loading time as much as possible.